Lately, I have been working with a company the fabricates the majority of Aesop locations in the tri-state area. Sometimes it amazes me the amount of leftover material that's gone to waste, but I've been getting more and more interested in creating a small scale line of interior objects through those materials.

Working with brass is interesting as the material can be cut with routers and tablesaws as it's considered a ‘non-ferrous metal’ and welding brass has an interesting chemical reaction when joined together, and can be left raw or clear powder coated to demonstrate its age or lock in its brilliant luster.

This project has been sent off to be nickel plated, and I'm currently working on the lighting bulb.

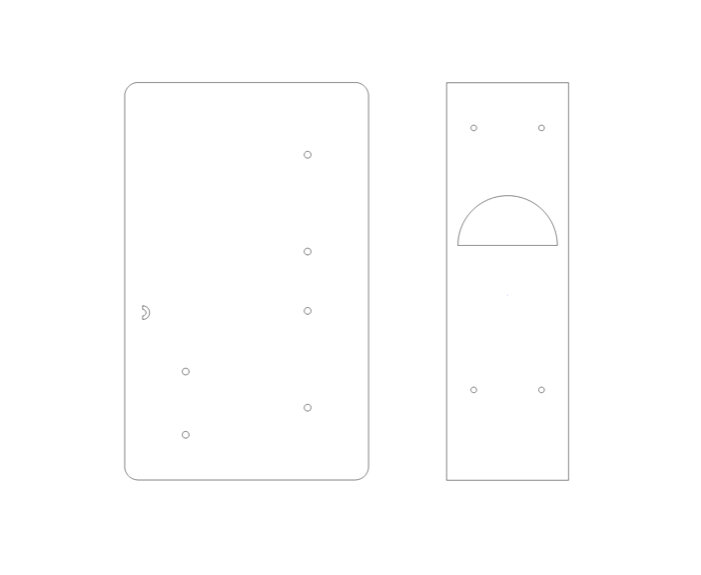

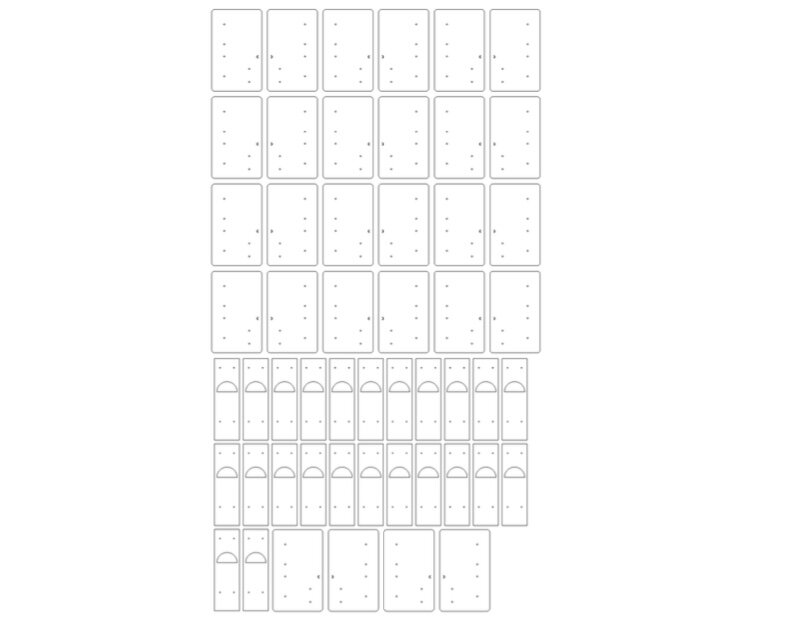

Process: Detailed drawing for client (before introduction to CAD), Fabrication process included, outsourcing for mirror machining diameter and stainless TIG welding for hot metal jointing provided by S.L.Wright Design Company, LLC.

24 sets in total were provided for retro-fit elevator door units. All geometry of exterior latch’s and flush pull handles provided by S.L.Wright Design Co, LLC.